GuEST COLUMN

SCROLL

Cobots Are Changing Manufacturing Forever

The market is expected to grow by 175% over the next decade

Collaborative robots (cobots) don’t get sick, take their time getting tools, crash after lunch, or have bad days. Cobots meet daily standards efficiently through laser-focused performance, which leads understanding and defining metrics.

Consistency

Cobots working on the industrial floor can be deployed for a wide range of duties. Although the highly automated car manufacturing sector remains the most utilized industry for electro-mechanical machines, cobots and other forms of automation are now entering more sectors.

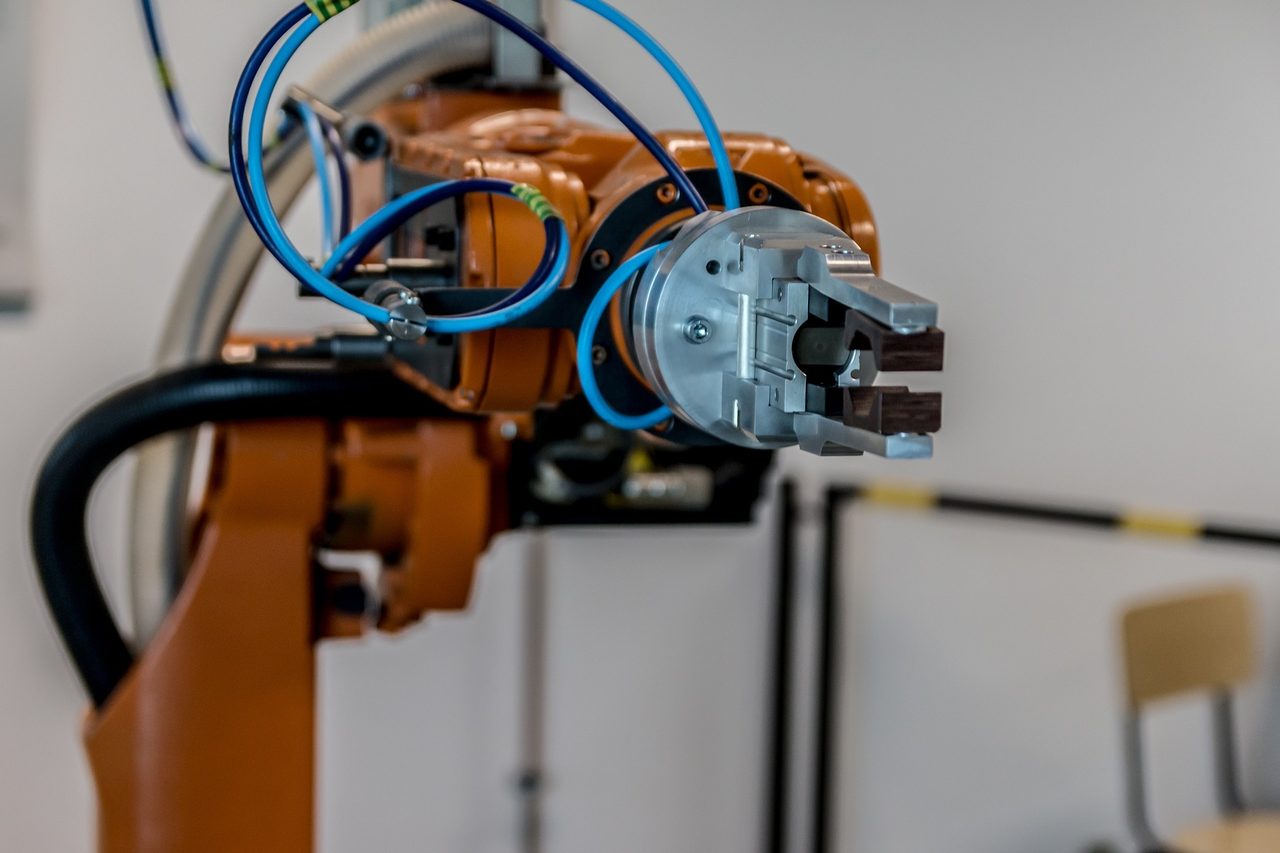

A cobot at work.

Photo courtesy of Daedalus Industrial

Currently, about 15% of businesses use AI, but 31% plan to add support for it over the next 12 months. In addition, the industrial robotics market is predicted to grow by 175% over the next decade.

Cobots are working alongside their human counterparts in every sector of manufacturing.

Photo courtesy of Pixabay

Benefits

At one time, traditional workers were afraid robotic applications would take over the workplace, and, perhaps, the world. However, cobots are working alongside their human counterparts in every sector of manufacturing — doing jobs that, in the past, resulted in permanent injuries or even death.

Robotics used in manufacturing are subject to two ISO standards: Robots and Robotic Devices-Safety Requirements for Industrial Robots, and Robot Systems and Integration.

Cobots are installed with force limitations, rounded edges, and non-pinching joints. They are also lightweight, portable, and ideal for various tasks within a factory.

Service cobots can be used for information in public spaces, transporting goods, or providing security. Industrial cobots have several applications, including pick and place, packaging and palletizing, assembly, machine tending, surface finishing, quality testing, and inspection.

Cobots can be used all over the factory floor in a variety of production functions.

Photo courtesy of Pixabay

Cobots can be used all over the factory floor in a variety of production functions, including those listed below.

- Manual pick-and-place, one of most repetitive tasks performed by human workers today.

- Machine tending, which demands workers stand for long hours in front of CNC machines, injection-molding machines, or other similar devices.

- Packaging and palletizing, the derivative of pick and place.

- Process tasks that require a tool to interact with a workpiece, including gluing processing, dispensing, or welding.

- Quality inspection as it involves full inspection of finished parts, high-resolution images for precision-machined parts, and part verification against CAD models.

- Finishing tasks — when performed human operators require a manual tool and large amounts of force that can cause injury to the operator.

Jacob Burgess

Jacob Burgess the business development manager at Daedalus Industrial. He is a graduate of Tri-County Technical College and attended Erskine College in the Business Administration program.