Why do batteries fail when you need them?

Prevent downtime with maintenance and monitoring

“Hurry up and wait.”

This timeless expression applies to so many situations, situations — ever rushed. Ever rushed to the doctor’s office just to wait forever before they call you back? Most batteries live their entire life in this perpetual purgatory just waiting for their moment to shine. Usually they are in a flashlight, remote control, or garage door opener, but batteries also backup mission critical systems, telecom equipment, and other critical appliances we need when the grid goes down. Too often, though, many of these batteries don’t work when they are needed the most. These batteries fail, and there are many reasons why. Most importantly, there are a few things we can do to prevent these failures and make sure the lights stay on.

Batteries provide power to utility control systems, industrial plants, and critical communications systems when the power fails. Traditionally, lead-acid batteries have been used for backup. The two most common lead-acid chemistries are flooded lead-acid (FLA) and valve-regulated lead-acid (VRLA). These are both simple combinations of sulfuric acid and lead plates in plastic containers. During the charge process, the positive plates change to lead peroxide, and the negative plates turn to pure lead. During the discharge process, the acidity of the electrolyte solution increases, and the specific gravity of the solution decreases. Both lead plates now begin to change to lead sulfate. That continues until there is no potential difference between the plates, though this should be avoided.

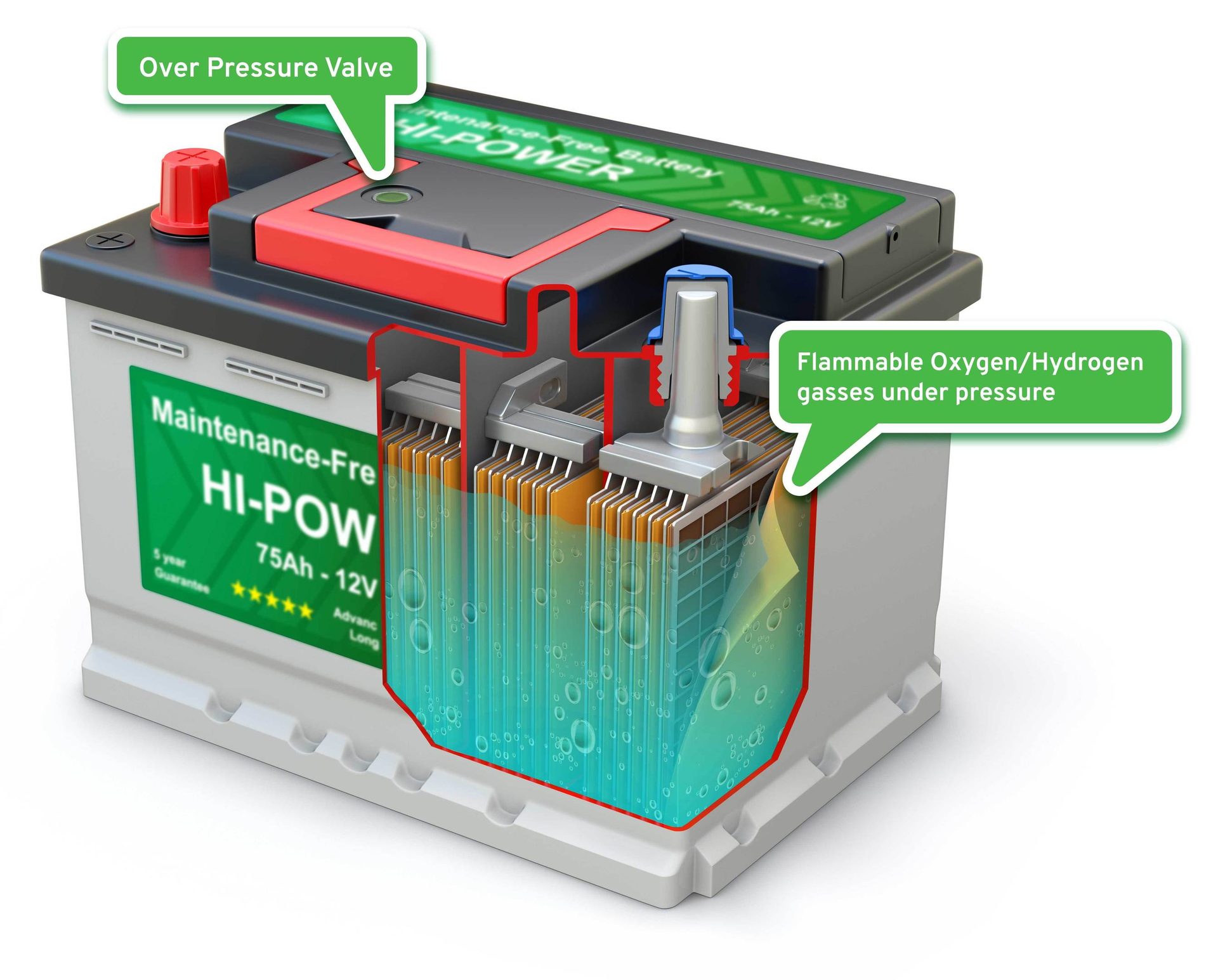

FIGURE 1: A valve-regulated lead-acid battery.

Images courtesy of Green Cubes

All batteries, including lead acid, require maintenance and monitoring to perform optimally and prevent damage. Batteries are considered wear items and do wear out as they are used. Like brake pads on a car, batteries can wear out faster if used aggressively. During normal use, a lead-acid battery generates both oxygen and hydrogen gases. It's important to manage these gases properly in an FLA battery by venting them to the atmosphere outdoors to prevent the risk of an explosion. Therefore, all battery rooms should have a ventilation system for lead-acid batteries. This is the reason operators must perform periodic maintenance and refill the FLA batteries with distilled water, because this gas generation consumes some of the H2O in the electrolyte solution. If the water level ever falls below the top of the lead plates, the lead will become irreversibly damaged, and the battery will lose performance. Another problem with FLA batteries is sulfation precipitation. During normal operation, lead sulfate forms on the plates. The problem is when this lead sulfate flakes off and falls down in the battery electrolyte solutions. This sulfate, over time, can build up at the bottom of the flooded cell “jar” (jar is a term used to describe the usually plastic container the plates and electrolyte are in. At one point in time these were glass jars, and the term has stuck). Sulfate flakes will build up over time, at the bottom of the jar and reduce performance of the battery and can even cause “soft shorts,” increasing the self-discharge of the cell. Finally, the sulfate can just build up over time on the lead plates due to use and reduce performance by preventing electron exchange. In summary, the main failure modes of FLA batteries — low water, sulfate build up, and over sulfation — are all preventable with constant monitoring and maintenance.

VRLA batteries alleviate some of these maintenance and performance issues and were developed in the latter half of the 1900s. While these batteries still use lead plates and sulfuric acid, they also introduce two key mechanical differences: Separating the lead plates is a fiber glass mat saturated with liquid electrolyte, and the whole assembly jar is sealed from the atmosphere. Since the jar now contains the oxygen and hydrogen generated by the battery, the additional pressure causes the two elements to recombine into water. This eliminates the maintenance need to check and top off water levels. This also eliminates the possibility of contamination in the electrolyte. Since this does increase the pressure inside the jar, a pressure-relief valve must be fitted to prevent explosion risks. Additionally, the connections must be checked periodically since they can become loose. It's typically not advised to perform too many equalization cycles on a VRLA, as that will generate excessive gas pressure, causing the vent to open. The result is that the electrolyte in the battery will no longer be sufficient to carry charge, and the battery will fail to operate. This type of failure happens due to overcharging, excessive equalization, or damaged seals — since water cannot be added to VRLA batteries, this is a major source of failure.

The failure mechanisms for the most common lead-acid types are well-understood. These are internal corrosion, sulfation, and loss of electrolyte as described above. These failures are caused by lack of maintenance, deep frequent discharges, frequent overcharge, and prolonged elevated temperature exposure.

FIGURE 2: Failed lead-acid batteries at Ajo Historical Museum.

When a lead-acid battery is overcharged, positive plate grid corrosion and gases are generated, causing pressure, venting, grid damage, and reduce electrolyte levels, reducing electrolyte levels and grid damage. If a lead acid battery is under charged, it's prone to sulfation, blocking the ability to discharge. There is an exceedingly small voltage window (2.25 to 2.27 V) to maintain a charge and this must be adjusted for ambient temperature. Battery experts call this “dancing on the head of a pin.” Therefore, it's quite common to over or under charge lead acid batteries, and, when discharged, they will not operate due to sulfation, grid damage, or loss of electrolyte. Choosing the right charger, and properly configuring the charge settings, is critical to prevent these issues.

It's well-known that lithium-ion batteries are becoming more popular in stationary applications as a backup power supply. Lithium batteries provide high energy storage in a small space, are lightweight, and offer a long life span. Although they boast many advantages, lithium batteries are not immune to failure.

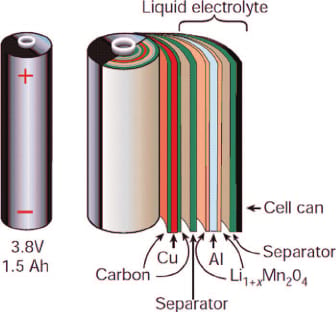

FIGURE 3: Components of a lithium-ion cell.

There are three main components of any lithium-ion battery, including the lithium-ion cell, the battery management system (BMS), and the mechanical enclosure. There are several distinct differences between lithium cells and lead-acid batteries. A lithium-ion cell is composed of a graphite (carbon) anode, polymer separator, cathode strip, and just enough electrolyte to saturate the separator. These three components can be packaged in cylindrical metal cans, foil pouches, or rectangular metal boxes, and then sealed airtight. One advantage of this construction is that they can be mounted in any orientation, even upside down, since the components are packed in so tightly.

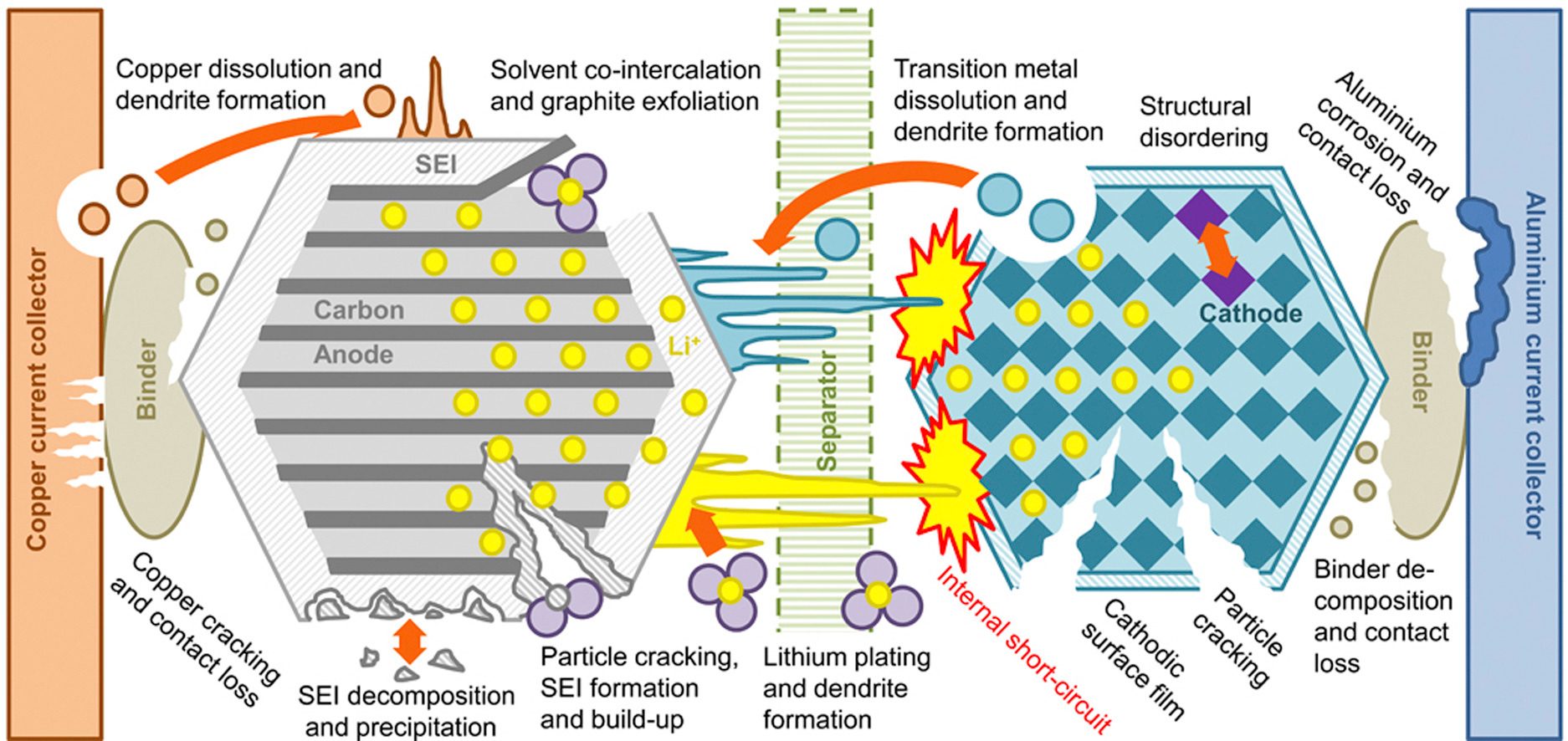

FIGURE 4: The mechanics of degradation in a lithium-ion cell.

Any time energy is stored in a system, there is the possibility of failure. The four main causes of lithium-iron phosphate (LFP) battery cell failures are short-circuit, deep discharge, overcharge, and elevated temperature. Figure 3 shows all the mechanics of failures and degradation in lithium-ion batteries. Every Lithium-ion battery has a BMS to prevent these four types of abuse. BMSs continually monitor the voltage, current, and temperature of the battery and compare them to programmed thresholds. If any of the parameters exceed the thresholds, the BMS will disable the battery and protect the cells. Typically, a fault has occurred in the charger or load circuit. Once the fault has been removed, the battery automatically recovers. Features, such as fuel gauging, data logging, remote monitoring, and remote control, are available on premium BMSs.

While a good BMS will keep a battery safe, the battery use case can affect the life expectancy. At a minimum, the battery must protect against over- and under-voltage, short-circuit, and use at extreme temperatures. However, there are best practices to prevent premature battery wear. Two common circumstances that can prematurely wear out lithium-ion batteries are prolonged over discharge and elevated temperatures. If a lithium-ion battery is discharged to zero percent state of charge (SOC) and left for an extended period, the cells could be over discharged and damaged. This extended period is usually measured in days to weeks. To prevent this, a more sophisticated BMS will keep a small amount of charge in reserve and enable a low-power mode when the battery is at zero percent SOC. This extends the time before damage to many weeks or months. This type of function is built in unnoticeably to operators and provides significant value in protecting energy storage assets. A similar function exists in lead-acid systems using a low-voltage disconnect setpoint.

Elevated temperatures are the enemy to all battery chemistries, as components of the chemistry begin to break down in nonreversible reactions. Lithium-ion batteries are resilient to elevated temperatures but still affected by prolonged exposure. It is the operator and use case that are responsible for maintaining a reasonable battery temperature. The ideal temperature range for lithium-ion batteries is 10° to 35°C, or 50° to 95°F. Lithium-ion batteries slowly degrade in elevated temperatures and will have lower discharge capacities after exposure. LFP cells are particularly resilient in elevated temperatures for two reasons. First, the chemical bonds in the cell components are extremely strong and can resist degradation at higher temperatures. And, second, LFP cells inherently have a high life cycle from Day 1, with over 3,500 cycles expected — so even with some mild degradation, thousands of cycles can still be achieved.

Both lead-acid and lithium-ion batteries work well as stationary energy storage mediums for mission critical communication systems. All batteries are prone to failure from lack of maintenance or abusive conditions. Since both of these batteries live the "hurry up and wait" life, there is ample opportunity to fail when they are needed the most.

JD DiGiacomandrea

JD DiGiacomandrea is the product marketing engineer for Green Cubes Technologies. He has over a decade of experience designing lithium batteries and systems for the military, medical, and industrial markets. DiGiacomandrea holds a Bachelor of Science in electrical engineering from Clarkson University and a PE license from the State of New York.

[KanawatTH] [Creatas Video+ / Getty Images Plus] via Getty Images